For over 60 years the electronic industry has used a tin lead eutectic solder alloy for soldering applications.Lead is a well-known toxic metal and it is hazardous for healthand environment. Now the primary concern is from ground water leaching of lead bearing solder in electronic products ultimately disposed in landfills. The lead bearing alloy solder seemingly ran foul with the advent of potential legislation that would ban or limit the use of lead due to environmental degradation and health hazards. Thus the use of lead-free solder is now essential.

Being a leading and responsible solder manufacturing company, Khanna Traders & Engineers has taken the initiative to develop and manufacture “Lead free materials” for soldering. KTE is conscious of the need for their products to be compatible with the environment and legislation .For the past 20 years , our R&D team has been fully engaged in this field for further development of various compositions of lead free solders.So,for the sake of the environment we say “GO GREEN …GO FOR LEAD FREE”

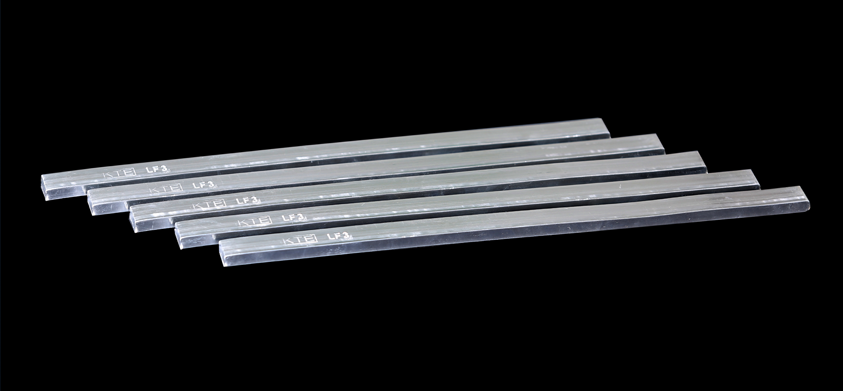

We have developed wide range of lead free products keeping in mind the quality, reliability and reasonable cost. The most commonly used SnAg , SnAgcu and Sn / Cu ++ solder alloys have already been successfully manufactured andarebeing supplied to most of our valued domestic and multinational customers.

KTE manufactures many compositions of lead-free solder alloys which are listed below with their properties and recommended application.

| PRODUCT CODE | COMPOSITION | MELTING POINT °C | TENSILE STRENGTH Mpa/min | RECOMMENDED APPLICATION |

|---|---|---|---|---|

| LF 1A | Sn95.5/Ag4.0/Cu0.5 | 217-218 | 37 | Used in electronic , electrical and components |

| LF 2 | Sn96.5/Ag3.0/Cu0.5 ( SAC 305 ) |

217-219 | 37 | Eutectic alloy . Suitable forall types of pcbs .Excelellent soldering results in wave soldering and good SMTprocess |

| LF 2 A | Sn 97/ Ag 3.0 / Cu 0 ( SAC 300 ) |

Replenishment ( Top up ) alloy of SAC 305 to stabilize copper in solder bath | ||

| LF 3 | Sn99/Ag0.3/Cu0.7 ( SAC 0307 ) |

225-227 | 25 | Most common solder alloy suitable for soldering of multilayer , PTH and single sided pcbs. Used in wave, dip and HAL soldering applications |

| LF 8 | Sn99.7/Ag0.3 ( SAC 0300 ) |

225 | Replenishment ( Top up ) alloy of SAC 0307 to stabilize copper in solder bath | |

| LF 11 | Sn99.2/Cu0.6/Ag0.1 ( SAC 0107 ) |

217-228 | 32 | Low silver contents . Performance same as SAC 0307 |

| LF 11 A | Sn 99.9 / Ag 0.1 ( SAC 0100 ) |

227 | Replenishment ( Top up ) alloy of SAC 0107 to stabilize copper in solder bath | |

| LF 15 | Sn99/Cu0.6/Bi0.4 ++ | 219-225 | 32 | Low cost proprietary lead free alloy .No Silver contents . Application & performance same as SAC 0307 & 0107 |

| LF 9 | Sn99.3/Cu0.7 | 227 | 28 | General purpose lead free alloy for soldering of electrical / electronics components and pcbs |

| LF 5 | Sn99.0/Cu1.0 | 227 | 32 | Best suitable for electricals and metal components |

| LF 16 | Sn95/Sb5 | 236-243 | 35.2 | Special alloy for automobile industry |

| SnZn | Sn80/Zn20 | 200 | 44 | For aluminium soldering applications . |

| Sn/ Zn/Bi | Sn / Zn/ bi 4.0 ++ | 190-197 | Low melting alloy for aluminium soldering |

KTE also manufactures Lead Free flux cored solder wire which is used widely in electronics / electricals telecom and automobile industry. These wires are available in different compositions, sizes and fluxes as listed below :

| FLUX TYPE | PRODUCT CODE | FLUX CONTENT% | SPREAD FACTOR% | DIAMETER IN mm |

|---|---|---|---|---|

| RA | LF 2 ( SAC 305 ) | 2 to 3 | >90 | 0.50 to 3.0 |

| LF 3 ( SAC 0307 ) | 2 to 3 | >90 | 0.50 to 3.0 | |

| LF 9 ( Sn / Cu 0.7 ) | 2 to 3 | >90 | 0.50 to 3.0 | |

| LF 1 ( Sn / Ag ) | 2 to 3 | >90 | 0.50 to 3.0 | |

| LF 5 Sn/ Cu 1.0) | 2 to 3 | >90 | 0.50 to 3.0 | |

| LF 16 Sn/ Sb ) | 2 to 3 | >90 | 0.50 to 3.0 | |

| RMA | LF 2 ( SAC 305 ) | 2 to 3 | >85 | 0.50 to 3.0 |

| LF 3 ( SAC 0307 ) | 2 to 3 | >85 | 0.50 to 3.0 | |

| LF 9 ( Sn / Cu 0.70 ) | 2 to 3 | >85 | 0.50 to 3.0 | |

| LF 1 ( Sn / Ag ) | 2 to 3 | >85 | 0.50 to 3.0 | |

| LF 5 Sn / Cu 1.0 ) | 2 to 3 | >85 | 0.50 to 3.0 | |

| LF 16 ( Sn / SB ) | 2 to 3 | >85 | 0.50 to 3.0 | |

| HALOGEN FREE &NO CLEAN | LF 2 ( SAC 305 ) | 1.2 to 2.2 | >80 | 0.50 to 3.0 |

| LF 3 ( SAC 0307 ) | 1.2 to 2.2 | >80 | 0.50 to 3.0 | |

| LF 9 Sn / Cu 0.7 ) | 1.2 to 2.2 | >80 | 0.50 to 3.0 | |

| LF 16 ( Sn /Cu 1.0 ) | 1.2 to 2.2 | > 80 |