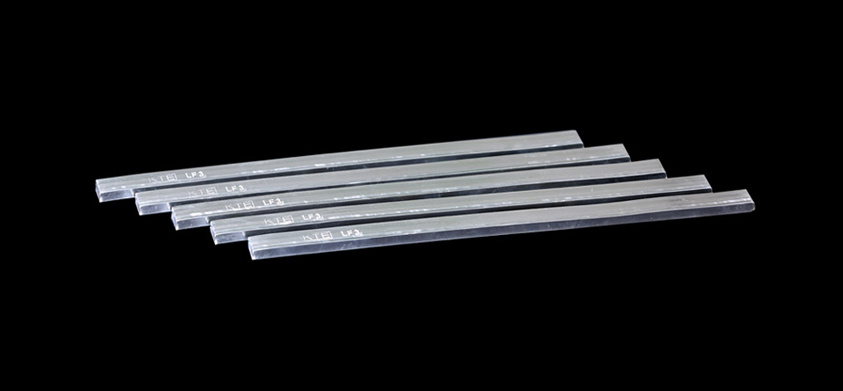

The best combination of the above features is found in BOND Solder sticks / bar. The quality of BOND solder sticks / bar is the best as compared to the other solder brands. BOND solder bar is made with the extrusion and vacuum processwhich conforms to a uniform alloy composition resulting in consistent and reliable quality. This process eliminates the contamination of metallic oxides and virtually drives out all sulphides,nonmetallic inclusion and other possible contaminations. In other solder bars the oxides can build up on the surfaces of molten solder to a brownish black mass which is called dross. But becauseof the special metal treatment done during manufacturing process, the surface of Bond solder alloy remains glossy in appearance for a longer time which results in less dross formation during wave soldering at the customer end.

KTE have a wide range of quality solder alloy as listed below :

| PRODUCT CODE | COMPOSITION | MELTING PONT °C | TENSILE STRENGTH(Mpa/min) | APPLICATION |

|---|---|---|---|---|

| SnPb | Sn63/ Pb37 | 183 | 49 | Eutectic solder for electronics , electricals , mobile and auto industry |

| SnPb | Sn60/Pb40 | 183-187 | 51 | General purpose solder. Suitable for hand soldering and dip soldering application |

| SnPbAg | Sn62/Pb36/Ag2.0 | 179 | 49 | Suitable for silver plated surfaces / components. It prevents silver leaching |

| SnPb | Sn 55/Pb45 | 183 – 212 | 44 | Low cost general purpose solder |

| SnPb | Sn 50/Pb 50 | 183 – 212 | 42 | Low cost general purpose solder |

| SnPb | Sn40/Pb60 | 183-238 | 45 | Low cost general purpose solder for electrical industry |

| SnPb | Sn 70 / ZN 30 | For aluminium soldering | ||

| Sn Pb | Sn 80/ ZN 20 | For Aluminium soldering | ||

| SnPbAg | Sn5/Pb93.5/Ag1.5 | 295 | 48 | For high melting point application |

High melting point solder is a special alloy that has been developed for high temperature application e.g. in electric motors, car radiators and high temperature lamps.

Low melting point alloy is developed for soldering of heat sensitive components.